Specialized Aerospace Components Engineered for Space

At Duval Precision Grinding, we welcome new and exciting challenges. Recently, a client sought our help in producing a custom fuel seal that would be part of a space rocket. All of the aerospace components we help manufacture with our precision grinding services must be made to exacting standards and tolerances. However, in the case of grinding parts that are space-worthy, we have to take extra care to make sure these fuel seals are absolutely airtight.

Custom Grinding Fixture Designed to Handle Large, Delicate Aerospace Components

The fuel seal ring was made of steel and had a chrome plating. It required a custom grinding fixture that could hold it with a firm but delicate grip during the grinding process; if this fixture failed, there was the risk of warping or cracking the plating. This sensitive task was no problem for our precision grinding experts, who have years of in-depth knowledge regarding grinding machinery and are accustomed to designing and building custom grinding fixtures for difficult parts.

The tolerances for this part were very tight—0.0002” on the diameters and 0.00002” for surface flatness. We performed a total of nine different grinding operations ranging from ID grinding to OD grinding and surface grinding; this ensured that every exacting blueprint specification was met.

Precision Lapping of the Chrome-Plated Part

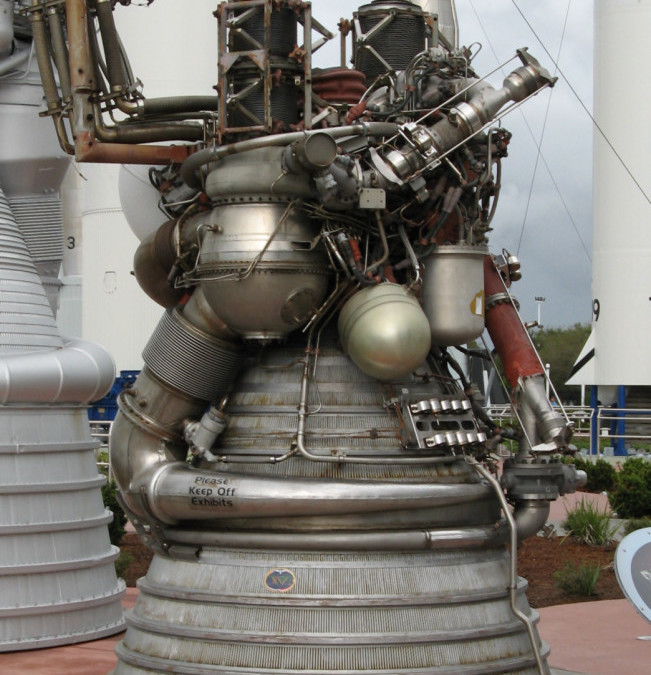

Example of the type of rocket engine that would include the fuel seal ring.

To ensure the fuel seal ring would achieve an airtight seal, the surfaces needed to be exceedingly flat. Any grinding process would leave a texture on the surface of the component. On a macroscopic level, minute grooves invisible to the human eye are fairly inconsequential. However, this project demanded that the surface would need to be flat—microscopically so. At Duval, we use a few different finishing methods to increase the flatness or smoothness of a part including superfinishing, honing, and lapping.

Lapping is a grinding process used to create the flattest of surfaces. The lapping process can refine the geometry of a part and will leave an extremely fine finish. The part is passed through a carrier fluid containing loose abrasives and then processed between one or two large, flat lap plates or platens. Compared to grinding and honing, lapping removes much less surface material and the end finish is fine enough to be measured in the micron and nanometer ranges.

Ready for Launch! On-Time Delivery, Every Time

To finish the grinding process on the rocket fuel seal rings, lapping helped achieve a super-flat surface. We measure the flatness of a surface via an optical flat and a monochromatic light source. This measuring method utilizes the wavelengths of light to measure flatness down to 0.3 microns or 0.0000116 inches. To give you perspective, the human eye can only see objects as small as 40 microns.

Duval’s sophisticated grinding experts were able to customize a grinding fixture and perform the necessary grinding operations on all of the requisitioned parts well within the time the customer requested. Precision is truly our only product—we take pride in providing you with excellent and expedient grinding services. Does your aerospace component have a special requirement for finely honed surfaces? Call or request a quote from the experts today!