Nuclear Power Components

Precision Grinding Components for Nuclear Power Applications

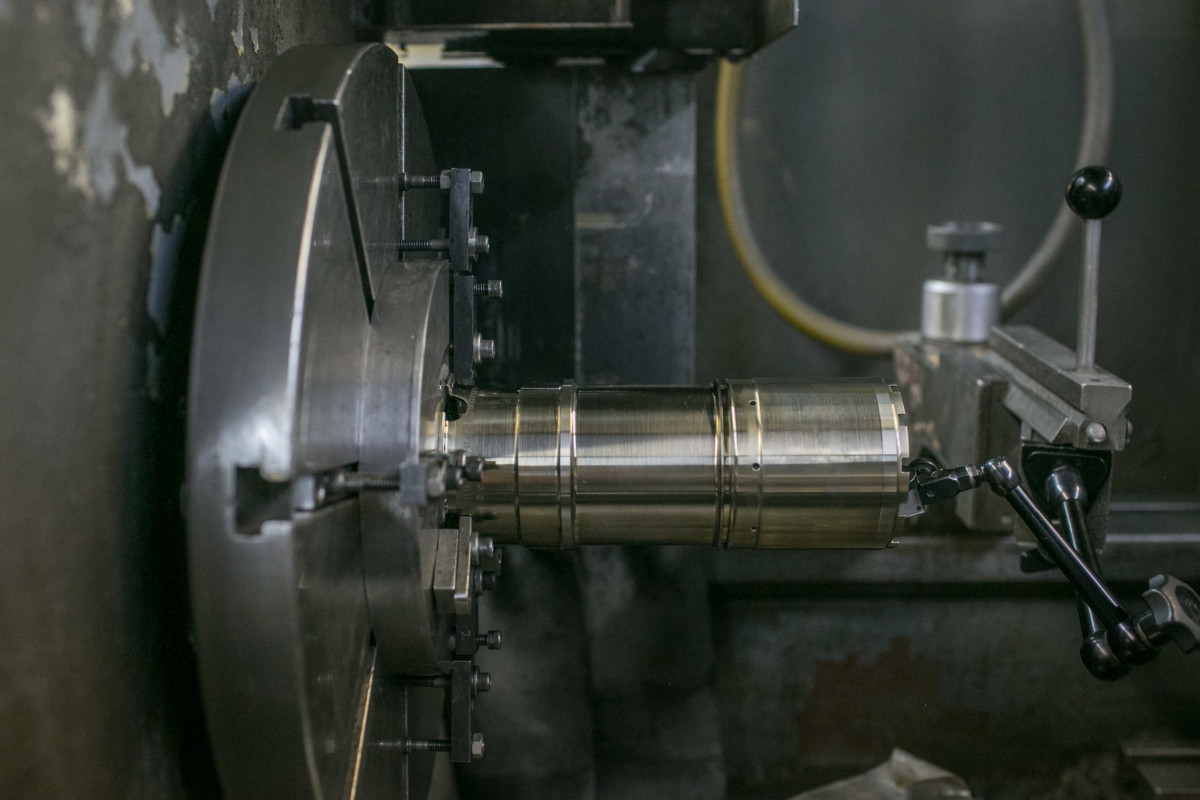

The nuclear power industry has some of the most stringent material and tolerance requirements to adhere to, which is why so many OEMs turn to Duval Precision Grinding for nuclear power industry components. Our qualified, experienced grinders produce expertly finished parts for a number of nuclear equipment applications, including latch housing assemblies, cartridge assemblies, guide tubes and more. Our grinders are trained to follow exacting quality standards and each part is subjected to in-depth quality inspections in order to guarantee your components are completed with perfect precision.

High-Quality Precision Grinding Service Provide Accuracy Where It Matters Most

Nuclear power equipment is subjected to some of the most demanding operating conditions on the planet. Parts and components must be made to exact dimensions to prevent erosion, damage, and chemical corrosion that could potentially lead to a contamination event. Our team understands that the utmost care and attention to detail went into designing every piece of nuclear equipment and it is our goal to ensure the parts we provide meet your exact specifications.

Nuclear power equipment is subjected to some of the most demanding operating conditions on the planet. Parts and components must be made to exact dimensions to prevent erosion, damage, and chemical corrosion that could potentially lead to a contamination event. Our team understands that the utmost care and attention to detail went into designing every piece of nuclear equipment and it is our goal to ensure the parts we provide meet your exact specifications.

Duval’s team includes highly trained operators, grinders, technicians, and programmers with the knowledge and experience to grind a wide spectrum of components while adhering to extremely tight tolerances and quality standards. We provide precision grinding of tolerances up to +/–0.0001”. Custom tooling and fixturing can be developed as needed to complete any components with uniquely challenging geometries.

Services and Capabilities for Nuclear Power Industry Applications

- ID grinding

- OD grinding

- Surface grinding

- Rotary surface grinding

- Jig grinding

Specialty Materials, Surface Coatings, and Plating

Corrosion and wear resistance are important material considerations in the nuclear power industry. Components must be expertly finished to resist the effects of everyday wear and tear. They must also be made of materials capable of withstanding the operating environment within a nuclear power system.

Many nuclear power components are made from 300 & 400 series Stainless Steel because of its superior resilience. Hard Chrome plating and Carbon Graphite liners are also common. Our team of experienced grinders is able to work with these materials in a way that won’t chip or damage the surfaces of the products. We are also able to work with a wide range of specialty materials as needed.

For more information about precision grinding services for nuclear power equipment, contact us today.

Precision Grinding for Nuclear Power Components

How to Choose A Precision Grinding Vendor