Medical Industry Components

Precision Grinding Services for Medical Industry Components

Duval Precision Grinding is able to provide high-quality precision grinding services for a variety of medical industry equipment and components. The experienced machinists at Duval are able to produce expertly finished parts for a number of medical applications, including implants, replacement joints, and more. Our comprehensive grinding services, quality standards and in-depth inspection protocols guarantee your components will be completed with flawless precision.

Maintaining Complex Geometries and Tight Tolerances for Medical Industry Parts and Equipment

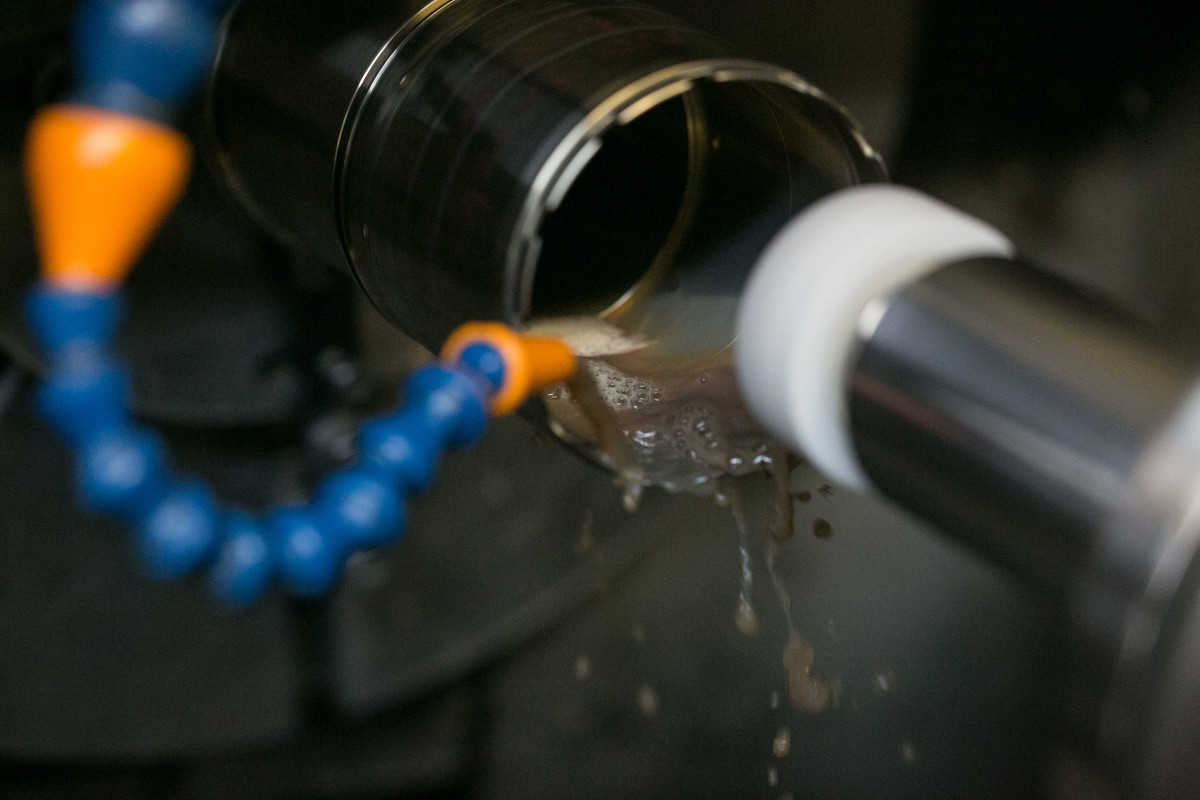

At Duval, every employee is committed to providing the unwavering precision required by the medical industry. Duval’s team of adept operators, machinists, technicians, and programmers are experienced with a versatile range of equipment and materials; this allows us to grind a wide spectrum of products with adherence to extremely tight tolerances and quality standards. Duval provides grinding services such as inner diameter (ID) grinding, outer diameter (OD) grinding, surface grinding, and jig grinding and we are able to meet demanding specifications on medical components with exceptional precision.

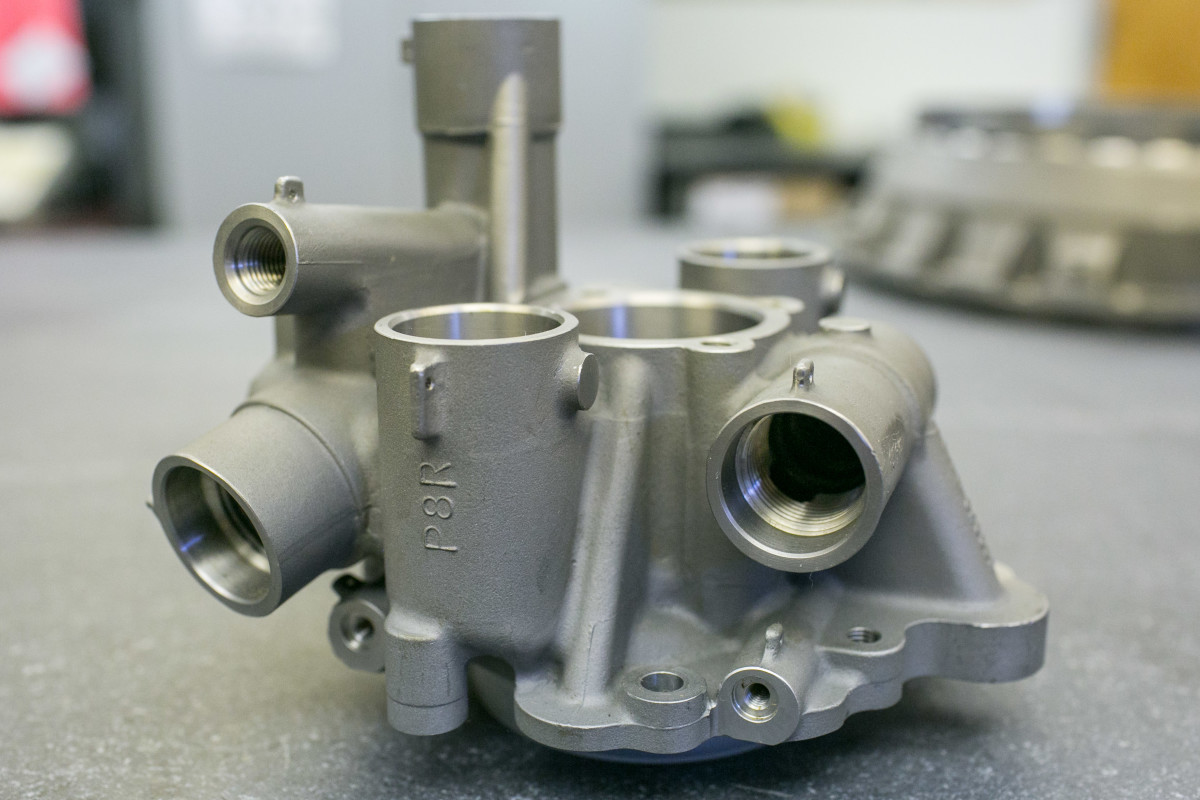

Medical industry equipment presents unique grinding challenges. The parts must be corrosion and wear resistant to ensure they are long lasting and able to withstand thorough cleaning and sanitization methods. Medical components are frequently made with stainless steel and titanium for their corrosion and wear resistance. Our team of experienced grinders is able to work with these materials in a way that won’t chip or damage the surfaces of the products.

Additionally, our team develops custom tooling and fixturing when required to complete components with unique or challenging geometries.

Services and Capabilities for Medical Equipment Manufacturing

- Shot peen

- Finish grinding

- ID grinding

- OD grinding

- Surface grinding

- Rotary surface grinding

- Blanchard grinding

- Jig grinding

- ID honing

- Lapping

- Super finishing

- FPI (Fluorescent Penetrant Inspection)

- MPI (Magnetic Particle Inspection)

- NDT (Non-Destructive Testing)

High-Quality Medical Equipment Parts via a Coordinated Supply Chain

All components are handled carefully throughout all shipping and grinding processes. Duval Precision Grinding will also coordinate supply chains as necessary to provide expertly finished parts that meet your specifications.

Industrial Automation Equipment and Machinery Grinding Experts

How to Choose A Precision Grinding Vendor