Precision Grinding Services for Aerospace Landing Gears

For seventy years, Duval Precision Grinding has been committed to providing aerospace OEMs with the highest quality products possible. All forms of aviation depend on landing gears that are safe, reliable, and resilient. Duval accommodates these stringent requirements by embracing technologies such as cutting-edge coordinate-measuring machines (CMMs), and fostering the growth of our highly qualified and experienced team.

Qualified and Experienced in Aerospace Component Grinding

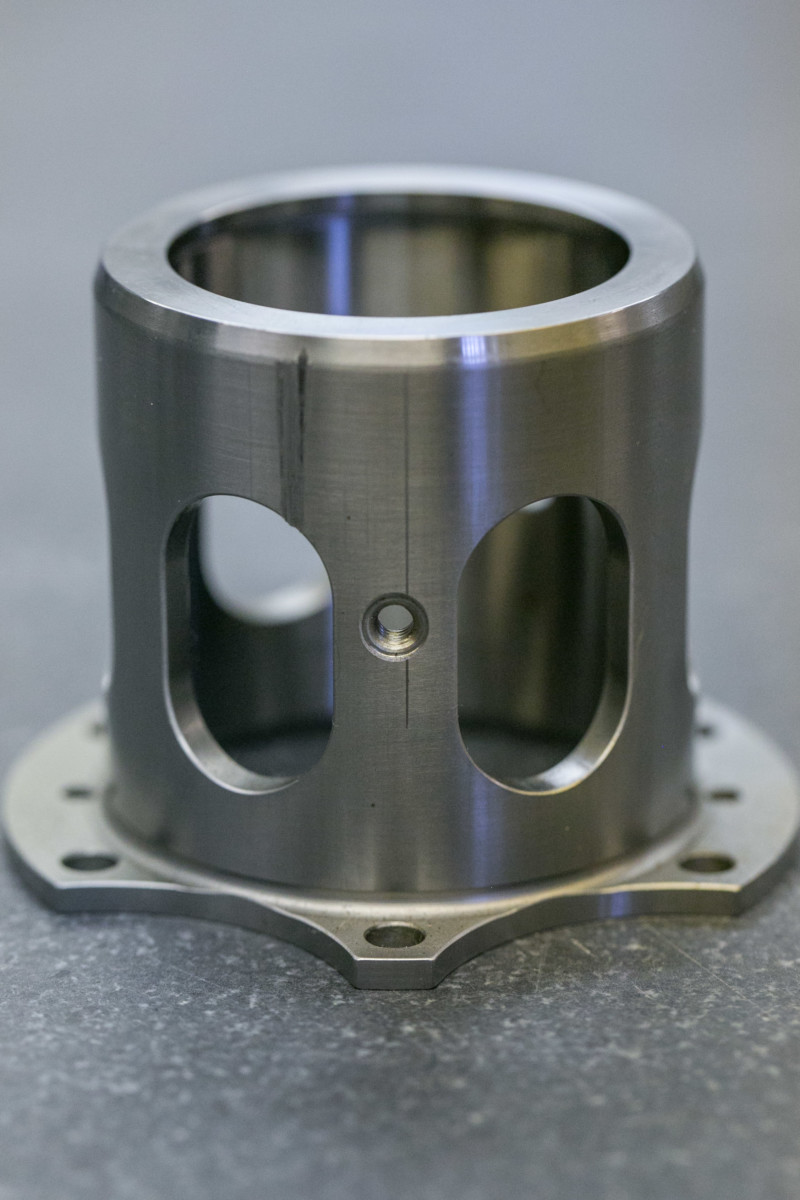

“Precision is our only product” is more than just a company catchphrase at Duval. Every employee is committed to meeting the growing demand for landing gears and other flight-critical components. Because the quality of aircraft components is so crucial, Duval engages a full team of adept operators, machinists, technicians, and programmers. This experience paired with versatile equipment allows Duval grinders to grind a wide spectrum of products with tight tolerances. Duval provides grinding services such as inner diameter (ID) grinding, outer diameter (OD) grinding, surface grinding, and jig grinding, which allows them to meet exacting specs on a variety of complex, high-performance components with exceptional precision.

Able to Handle High Tolerances and Difficult Coatings

Aerospace landing gears and components present unique grinding challenges. The parts must be corrosion-, wear-, and thermal-resistant while also providing the necessary strength to withstand the demanding forces placed upon them by the aircraft.

Although the steel in landing gears is strong and flexible enough to withstand the forces of landing, chrome coatings and high-velocity oxygen fuel (HVOF) coatings that are often used to reduce frictional wear and increase corrosion resistance. These coatings tend to be very hard and brittle. Our team of experienced grinders is able to work with these materials in a way that won’t chip or damage the surfaces of the products.

Heat treatments are available as a way increase the performance of alloys like 300M and HP9-4-30 to better achieve each customer’s goals. However, heat treatments can distort a part, causing it to bend or bow slightly. Our team is able to compensate and adjust for these low-level distortions and ensure an even plating layer on the part, keeping components usable and preventing product loss.

Maintain Your Production Schedule

In order to meet increased demands, Duval has recently invested in a new OD grinder, modified our jig grinding capabilities to handle larger parts, and expanded our rigorous inspection processes. This additional equipment allows our team to reduce turnaround times and increase the range of part sizes with which we can work.

Customer satisfaction is of paramount importance at Duval Precision Grinding. We are always available to customers to communicate the status of parts and provide quick and responsive service. Manufacturing landing gears and components often leads to delays, often due to engineering changes. By expanding our capacity, we can expedite our operations and help OEMs get the job finished on time, even if it is already behind schedule.

Duval Precision Grinding is dedicated to exceeding customer expectations and industry demands. This commitment to timely, precise, and reliable service is why aerospace OEMs choose Duval.

Experts on Landing Gear Grinding

How to Choose A Precision Grinding Vendor