Precision Grinding For Engine Components Made from Aerospace Alloys, Inconel and Titanium

Duval Precision Grinding is able to work with a wide variety of materials and coatings, including specialty alloys such as Inconel and Titanium. Quality parts begin with quality materials, and for some industries, it’s absolutely critical. That is why we make it a priority to ensure our machinists know the ins and outs of how best to work with all material options for any component we produce.

Recently, our team completed work on a large order of engine components for commercial aircraft. Although the customer was very involved in the inspection process and coordinating logistics, they had very limited finishing capabilities in-house and were relying on Duval to provide the finishing touches on a variety of flight-critical components.

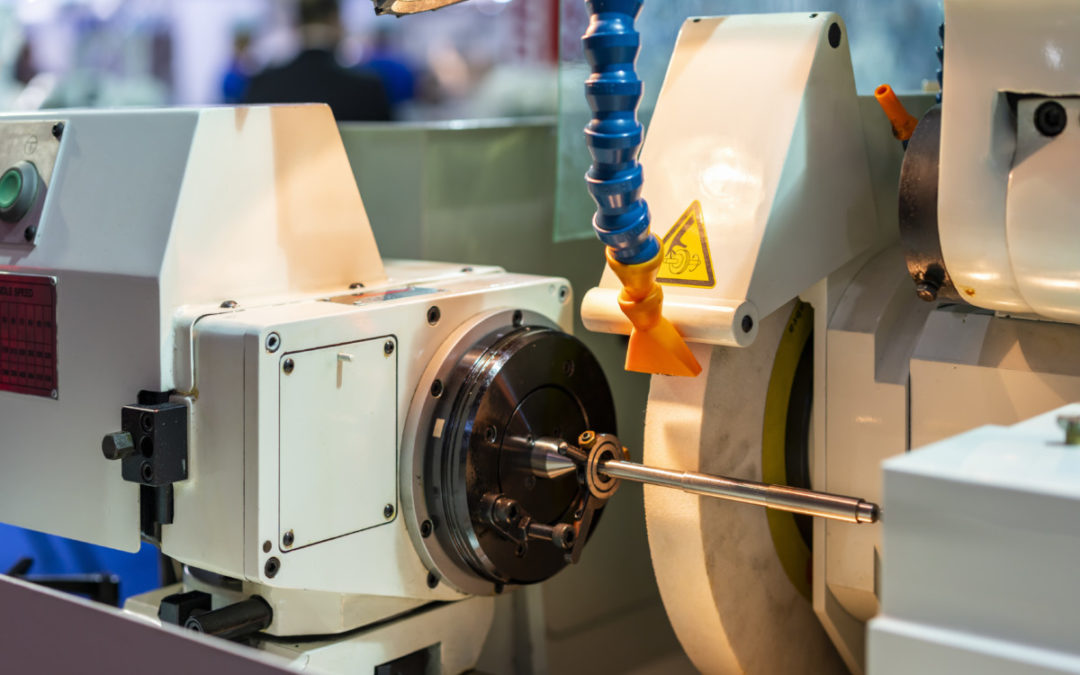

ID Grinding, OD Grinding, and Surface Grinding Specialty Alloys

The order included spacers, compressor disks, and heat shield assemblies made from a selection of specialty alloys including 300 Series Stainless Steels, Inconel, and Titanium. These materials were chosen for their high resistance to heat, corrosion, and physical damage. Several pieces also had a plasma coating to further increase durability.

Processing the parts was relatively straight-forward, however, when working with specialty alloys, it is vital to send these materials to an experienced grinding house. An experienced grinder will be able to select the proper wheels and control the speeds & feeds with care to ensure high-quality results every time. Duval has worked with specialty alloys on past projects in a variety of industries, such as Inconel compressors for turbine engines and titanium joint replacements for the medical industry.

To complete the order, each piece would need a series of OD, ID, and surface grinding operations. The grinding operations went smoothly and each part was subjected to our rigorous quality inspection process. For this project, our team used manual inspection gages for inspection at the machine (Snap Gages, Bore Gages, height gages). A final check was performed on our CMM (Coordinate Measuring Machine). The customer was satisfied with the completed pieces.

For more information about precision grinding services for specialty alloys, contact Duval Precision Grinding today.