The experts at Duval have decades of experience working in rigorously regulated industries, such as FAA overhaul, aerospace, and even nuclear power. Several of our customers that specialize in manufacturing components for nuclear reactors. Over the years, they have trusted Duval Precision Grinding to provide them with the high-quality grinding and finishing results that ensure their equipment passes inspection and performs reliably.

Custom Tooling and Fixturing

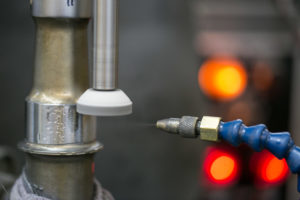

Recently, our team completed work on a particularly complex and important piece of equipment. The control rod latch assembly is used to position the rod cluster within the reactor core. Inserting the rods will slow the reaction that generates power while withdrawing them will cause the reaction to increase exponentially. The reactor can be “scrammed”, or shut down quickly, in an emergency by disengaging the latch assembly and allowing the rods in fall into the core via the force of gravity.

Duval’s team of grinders worked to complete a series of individual parts that make up the control rod latch assembly. The parts included a cartridge assembly, latch housing assembly, movable latch magnet, movable latch support and more. The parts were made of steel with either chrome plating or plasma coating, depending on their function within the finished assembly. In order to fulfill the specifications for each component and achieve the tight tolerances that were required, custom tooling and fixtures needed to be developed. To accurately position hole features, some of the parts required rotary indexing on a jig grinder.

Duval’s team of grinders worked to complete a series of individual parts that make up the control rod latch assembly. The parts included a cartridge assembly, latch housing assembly, movable latch magnet, movable latch support and more. The parts were made of steel with either chrome plating or plasma coating, depending on their function within the finished assembly. In order to fulfill the specifications for each component and achieve the tight tolerances that were required, custom tooling and fixtures needed to be developed. To accurately position hole features, some of the parts required rotary indexing on a jig grinder.

When Precision Matters Most, Trust the Experts

Duval’s capability to provide reliable, high-quality precision grinding services for complex components made them the most qualified choice to complete these jobs for the OEMs. Our team was able to fully process each piece for the rod latch assembly to the customers’ exact specifications. Each component was subjected to our stringent in-house quality inspection processes, as well as special quality audits performed by the customers. The components passed with positive remarks and the customers were overall satisfied with the work once complete.

To find out more about precision grinding services from complex nuclear reactor components, contact the experts at Duval Precision Grinding today.