Duval Precision Grinding works with a number of machine shops, helping the companies achieve the tight tolerances and specified finish requirements for the parts they’re working on. Recently, a client based out of Long Island, New York, contacted us for precision grinding services because one of their customers required a level of precision that they couldn’t meet in their own shop. Once they had machined the components, they sent Duval parts to have the finish grinding performed before returning the parts to their customers.

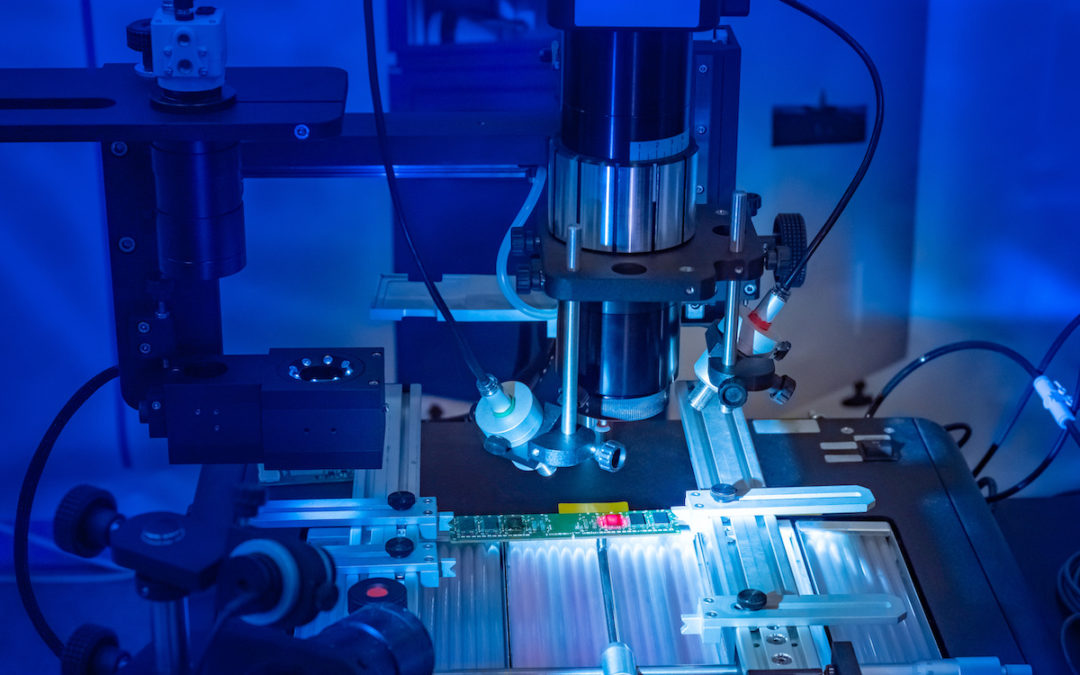

Grinding Chrome Shafts for Optical Coating Machines

The machine shop’s client is an OEM producing optical coating machines. The print requirements came directly from that client, who was subcontracting the chrome plating and OD grinding out to specialists to ensure they could meet the print requirements. While this is a fairly common scenario, it can lead to unanticipated challenges. In this case, the parts were delayed during the chrome plating process, so the machine shop reached out to us to see if we could make the grinding process go more quickly. We were able to work through the OD grinding process and prepare the necessary paperwork while the parts were in transit to minimize turnaround time for the client.

When the parts arrived, we were finally able to examine them more closely. The part was built from 300-series stainless steel with a rough envelope of 5″ by 5″, and included a hard chrome-plated shaft with a range of different tight tolerance diameters that needed to be finished ground. The machine shop decided to work with Duval because of our high level of experience performing tight tolerance precision grinding on chrome-plated parts and depth of expertise when it comes to working on precision shafts. As we started the process, we were able to meet the original client’s tight tolerances of 0.0003” or less.

Rapid Turnaround For OD Grinding

The OD grinding for this job took a total of eight days: three days to get the project through the new job layout and queue while processing and shipping the parts back to the machine shop took an additional five days. We were happy to work out a process that would minimize how much time the parts were in our hands. The machine shop had a job requiring the assistance of an experienced grindhouse, and we are committed to ensuring our clients achieve their end goals and tolerance needs.

At Duval Precision Grinding, we take pride in helping our clients meet their OD grinding and production needs so that they can get on with their projects. If you need precision OD grinding, please reach out to request a quote today.