Duval Precision Grinding was recently approached by a military contractor seeking grinding and finishing services for a precision inspection gauge. The inspection gauge was designed to simulate receiving the mounting apparatus for artillery. This inspection process ensured that artillery would be seated properly during installation. Maintaining accuracy would be a vital part of achieving the customer’s desired results for the finished product, so they came to Duval for the highest quality precision grinding services.

Custom Grinding Operations Ensure the Results You Need

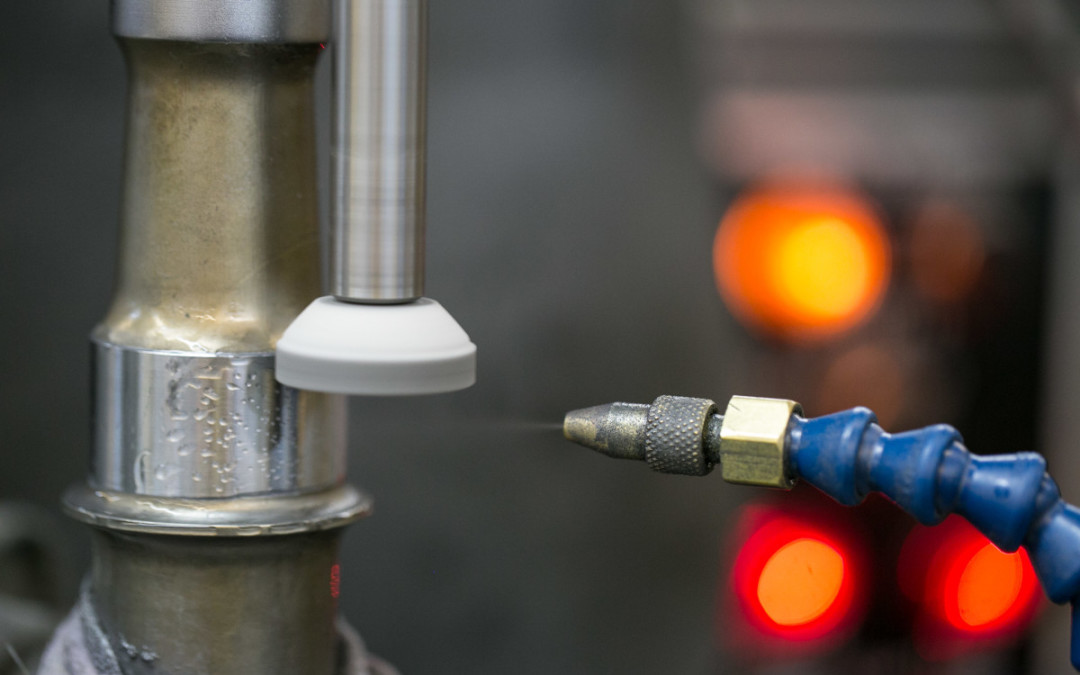

The unique, complex geometry of the inspection gauge and the tight tolerances required would make this piece a particularly challenging job. When grinding an object to a certain roundness and locating from an adjacent face, the smallest imperfections in that face can affect the outcome of the grinding process.

The unique, complex geometry of the inspection gauge and the tight tolerances required would make this piece a particularly challenging job. When grinding an object to a certain roundness and locating from an adjacent face, the smallest imperfections in that face can affect the outcome of the grinding process.

To help guarantee consistent adherence to detail, one of our most experienced grinding operators personally worked on the project from start to finish. Additionally, the customer requested the part be inspected after each grinding operation.

A normal jig grinding operation is performed on an inside diameter (ID) or outside diameter (OD) with precise sizing. This particular part required double-sided slot grinding. Since this is an atypical grinding request, achieving the results the customer needed would require a customized grinding process and a little creative thinking.

Experienced Grinders Guarantee Accuracy and Precision

The expert grinders at Duval Precision Grinding were able to rise to the challenge presented by the customer and provide them with a finished, quality part. At Duval, precision is our only product and we are always willing to apply our expertise in innovative ways to return a quality part, every time. For more information about precision grinding services for inspection guages and more, contact us today.