A producer of parts and subassemblies—for military aircraft, civilian aircraft, and the oil extraction and power generation industries—contacted Duval for the precision grinding of complex aerospace components. This customer regularly supplies individual components for the repair and completion of aircraft landing gear. This customer is also a supplier for the US Navy and the US Air Force, which meant speed, precision, and reliable quality were of the utmost importance.

Grinding Complex Aerospace Components and Intricate Parts

Chrome plated aerospace component before indexed precision grinding process.

The customer came to Duval to support their manufacture of a complex, chrome-plated aerospace component that required multistage aerospace grinding services to complete. The parts were made of stainless steel with chrome plating, so the interior of the drilled holes exposed the stainless steel, while the outer, flat surfaces and slots were coated in chrome. Inside a specific slotted section on the part were eight segments with four flat areas alternating with four curved sections. The four flat sections on the interior required precise indexing to accurately perform precision jig grinding and meet customer specifications.

This part was designed to spin during normal function, so meeting the tight tolerance requirements for this part was extremely important; it needed to move smoothly without rubbing against other components or otherwise impeding motion. The customer came to Duval Precision Grinding knowing our team could provide professional, seamless aerospace grinding services on this difficult job.

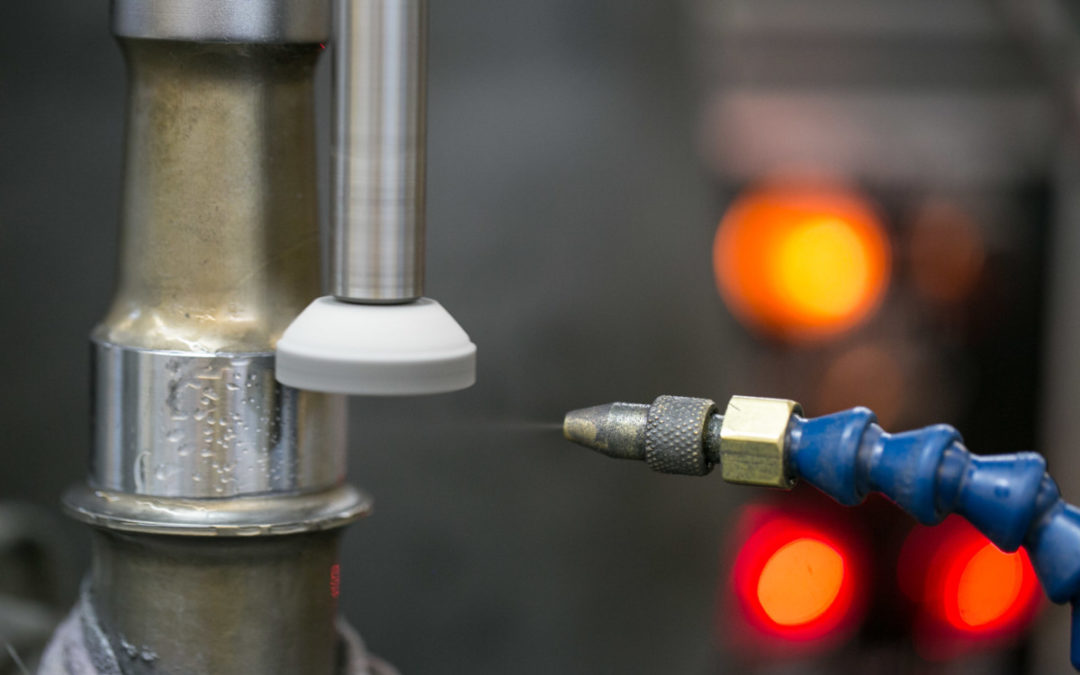

Multistage Jig, OD, and Radial Grinding Processes Ensure Optimal Results

Chrome plated aerospace component after indexed precision grinding process.

To perform these specialty grinding services, our engineering manager, Brian Gamache, worked with the customer and the Duval grinding team to outline the order of operations. Brian and his team recognized the importance of a repeatable process that produced high-quality results.

The small surface areas of the part and the complexity of the design made this a challenging job. The grinders at Duval Precision Grinding implemented specialty tooling and fixturing processes to ensure indexing was as precise as possible to meet the customer’s specifications. In total, the part took five separate grinding operations to complete: OD grinding, radial flat grinding, surface grinding, jig grinding and side wheel grinding.

Reliable Quality from the Precision Grinding Experts

Our team of expert engineers and precision grinders developed a reliable, multistage grinding process that produced quality results. The customer was so satisfied with the initial order, they sent a follow-up order for additional pieces to be completed over the next year. For precision grinding aerospace parts, contact the experts at Duval Precision Grinding.